- GST No. 07AAECS0290H1ZG

- Send SMS

- Send Email

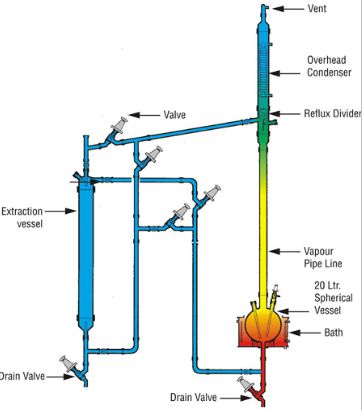

Extraction Units

Leading Manufacturers, Exporters, Wholesaler, Retailer and Importer of Liquid-Liquid Extraction Unit, Reaction Extraction Unit, Solid-Liquid Extraction Unit and Soxhlet Extraction Unit from Delhi.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Importer |

Preferred Buyer From

| Location | Worldwide |

This is a semi-batch unit designed for liquid-liquid extraction as a means of separation. Liquid to be extracted should be treated with solvent of different density. A liquid mixture is poured in the extraction vessel. Solvent in the reactor is boiled and condensed, and passed to the extraction vessel, from where liquid is extracted and is mixed with the solvent and passes to the reboiler. The process is repeated until extraction is complete. Solution is again evaporated to obtain the extract. The unit is complete with spherical vessel, heating bath, condenser, reflux divider, extraction vessel, and necessary pipelines and valves. The unit can be supplied with solvent feed arrangement either from the top or from the bottom, or with both arrangements. The unit is available in vessel size of 10, 20, 50, 100 Ltr.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Importer |

Preferred Buyer From

| Location | Worldwide |

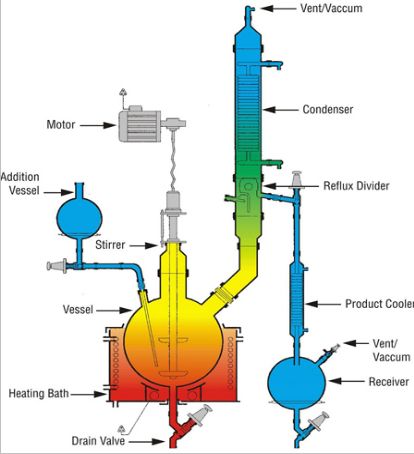

This is a general purpose batch reaction distillation unit to be operated at atmospheric pressure or vacuum. While heating bath heats and evaporates the contents of the vessel, the stirrer agitates to avoid heat spots. Vapors enter the condenser through reflux divider and get condensed. The condensate is then cooled by a product cooler and collected into a receiver. The unit is complete with a spherical vessel, drain valve, heating bath, thermometer pocket, liquid additional vessel, stirring assembly with drive, coil condenser, reflux divider, product cooler and receiver with drain valve.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Importer |

Preferred Buyer From

| Location | Worldwide |

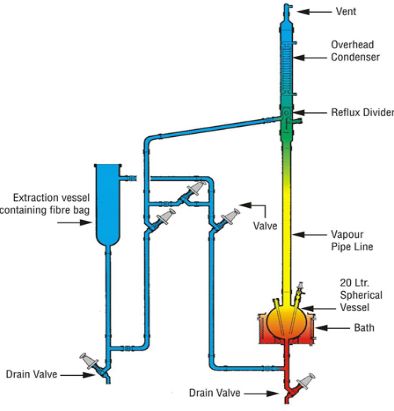

This is a semi-batch unit designed for solid-liquid extraction as a means of separation. The solid to be extracted is put inside a glass fiber bag and is placed in the extraction vessel. Solvent in the reactor is boiled and condensed, and passed to the extraction vessel, from where extract is mixed with the solvent and passes to the reboiler. The process is repeated until extraction is complete. Solution is again evaporated to obtain the extract. The unit is complete with spherical vessel, heating bath, condenser, reflux divider, extraction vessel, and necessary pipelines and valves. The unit can be supplied with solvent feed arrangement either from the top /or from the bottom, or with both arrangements. The unit is available in vessel size of 10, 20, 50, 100 Ltr.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Importer |

| Type | Automatic |

| Certification | CE Certified |

| Color | Transparent |

| Voltage | 220V |

| Brand Name | BORO G |

| Application | Laboratory |

| Material | Borosilicate 3.3 Glass |

| Temprature Capacity | 400 Deg C |

| Product Code | BSEU |

| Port | New Delhi |

| Payment Terms | L/C, T/T |

| Delivery Time | 7 Days |

| Packaging Details | Export worthy Packing |

Preferred Buyer From

| Location | Worldwide |