- GST No. 07AAECS0290H1ZG

- Send SMS

- Send Email

Heat Exchangers

Leading Manufacturers, Exporters, Wholesaler, Retailer and Importer of Coil Type Heat Exchanger, Glass Heat Exchanger and Shell & Tube Heat Exchanger from Delhi.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Importer |

| Size | Standard |

| Usage | Industrial |

| Type | Automatic |

| Material | Stainless Steel |

| Certification | CE Certified |

| Voltage | 220V |

Preferred Buyer From

| Location | Worldwide |

These items are widely used in the chemicals, pharmaceutical and allied industries for various duties like condensation, cooling, heating, evaporation etc. This is because of the special properties of borosilicate glass 3.3. The overall heat transfer coefficient of Borosilicate glass equipment compare favorably with many alternative materials because of its smooth surface which improves the film coefficient and reduce the tendency of fouling.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Importer |

| Size | Standard |

| Type | Automatic |

| Material | Glass |

| Shape | Cylindrical |

| Certification | CE Certified |

| Voltage | 220V |

| Finishing | Polished |

Preferred Buyer From

| Location | Worldwide |

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Importer |

| Material | Etc |

| Application | Pharmaceutical Industry |

| Brand | Boro G |

| Medium Used | Oil,Water,Air |

| Temperature range | -40degree C to 150degree C |

| No of DN | 80-300 DN |

| Glass Tube Thickness | 1.5 mm |

| Minimum Order Quantity | 1 Piece |

Preferred Buyer From

| Location | Worldwide |

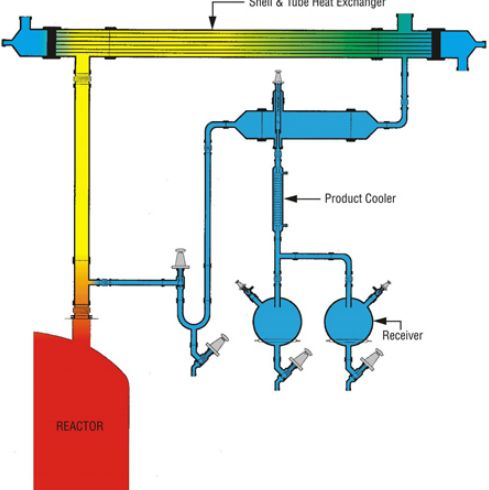

The Shell & Tube Heat Exchangers are available in various combinations of Glass/Metal, Metal/FRP in Shell & Headers. Shell & Tube heat exchanger consists of a cylindrical shell which houses a glass tube bundle. Tubes are sealed with shell with the help of PTFE tube sheets. Each tube is individually sealedwith tube sheets at both the ends. Baffles are provided in the shell to maintain state of turbulence of fluid as well as to hold the tubes.

Shell & Tube heat exchanger can be operated within a temperature range of -40° C to 150° C on either side. However, differential temperature should not exceed 120° C at any point. Also, these can be used predominantly under full vacuum, provided differential pressure does not exceed 3 Bar.

The range of overall heat transfer co - efficient in the shell & tube heat exchanger in most of the application range between 300 - 900 kcal/m², h,°C .These are available in different standard models from 3M² to 26M².

Glass Shell & tube heat exchangers can be used for condensation, vaporization, cooling and heating. They have come out to be more advanced and beneficial for its following advantages :-

- Higher Heat Transfer area in one unit

- Less pressure drop.

- Stuffing box sealing allows easy tube replacement